Automation kept factories alive in the 20th century—AI will decide who survives the 21st.

But most factories never get past the pilot. Why? Because AI requires mountains of labeled data and constant tuning.

Without a breakthrough in speed and autonomy, AI is just another science project.

Introducing VisionStream

Meet VisionStream, AI that watches your line, learns what "good" looks like, and catches up to 99.9% of defects—in under 60 seconds. No image labeling, line stoppage, or vision experts required.

Running on the edge, VisionStream is fully autonomous, accurate, and always on.

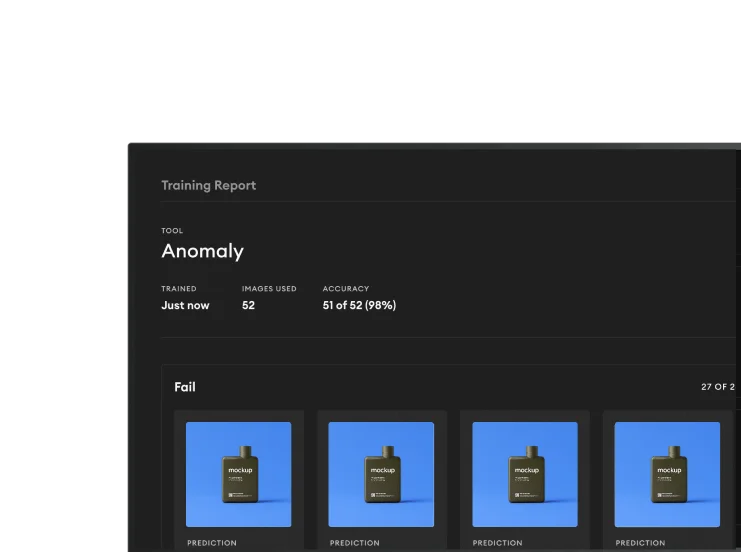

Cameras capture production parts, not staged defects

Edge controllers build AI models in under 60 seconds

Models predict with up to 99.9% accuracy at 1,000 ppm

Operators review edge cases and guide AI evolution

From One Line to Every Line

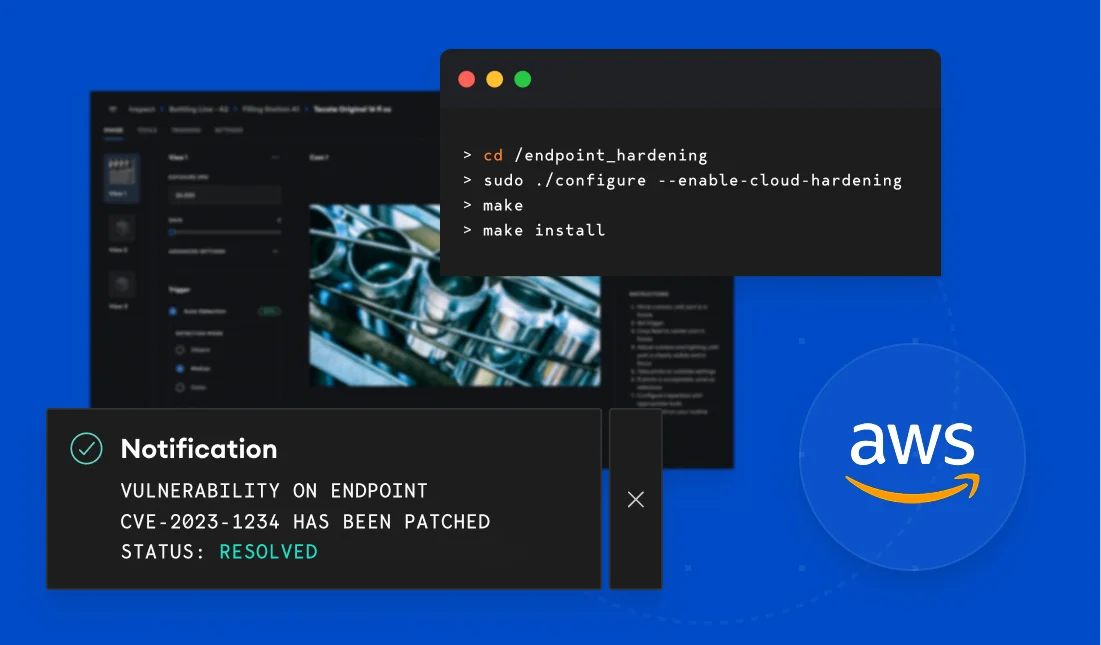

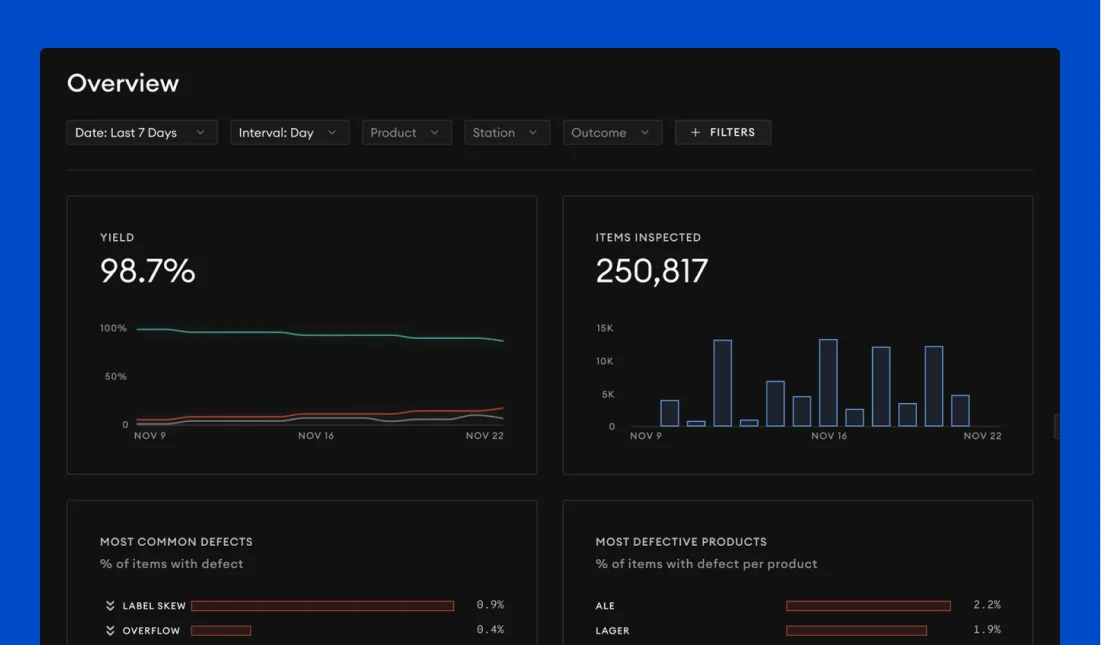

While VisionStream powers defect detection at the edge, QualityOS connects every line and every part in one cloud platform. Complete visibility. Factory-wide control.

The Complete Factory AI Stack

Hardware, software, and services—designed to plug into your factory, fast.

Industrial lighting, cameras, and controllers that inspect at 1,000+ parts per minute.

Cloud platform for traceability, analytics, and operational improvement.

Self-training AI that detects defects in seconds, without setup, rules, or tuning.

Certified partners for installation, monitoring, and ongoing optimization.

Compatible with existing cameras, PLCs, SCADA, OT, MES, ERP, and BI systems.

Inspect Everything

Automated inspection for any part, any line, and any industry.

For Every Industry

Manufacturers using QualityOS cut escapes by 95%, reduce manual inspection, and unlock operational insights—on day one.